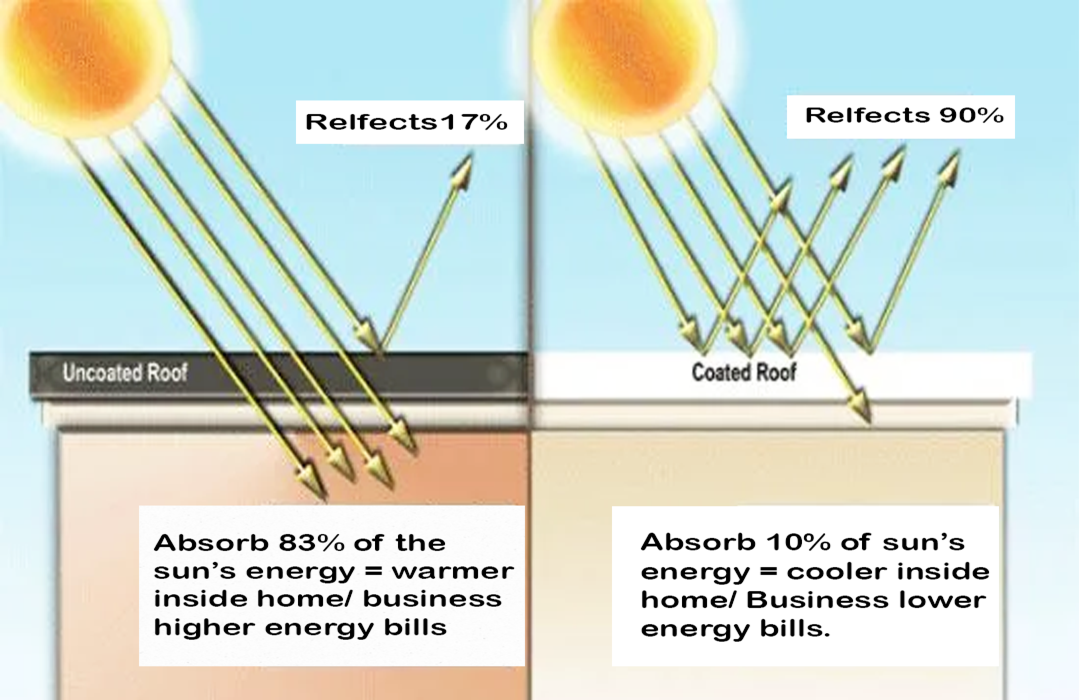

Elastoclad HR is a 100% acrylic waterproofing and heat reflective coating which is formulated with hollow core ceramic microspheres to dissipate and reflect solar radiation and also provide a long lasting elastomeric waterproof coating. The ceramic coating technology was developed originally for NASA space shuttles during re-entry to the atmosphere, the benefits provided are therefore substantial.

Elastoclad HR used on metal roof decks, silos, storage tanks, cold storage facilities, metal wall surfaces, concrete roofs, walls and electrical equipment boxes. Suitable surfaces to apply to include concrete, metals, timber, asbestos cement and brickwork.

The K value of various common building materials is shown below which provides the heat transfer property or the thermal conductivity of the material. The higher the K value the faster heat is transferred through a particular material.

| Material | K Value |

|---|---|

| Copper | 386.00 |

| Aluminium | 204.00 |

| Steel | 54.00 |

| Concrete | 1.00 |

| Brick | 0.70 |

| Asbestos | 0.17 |

| Elastoclad HR | 0.10 |

CONCRETE - Remove all debris and contaminants from the surface.

Optimum preparation will be achieved by high pressure water blasting.

Ensure the substrate is sound and carry out repairs

using a polymer modified repair material

Conpatch Conpatch from Cormix. Cormix Upstands, pipes, penetrations, roof fixing,

joints etc. must be detailed and flashing used as appropriate. Ensure

there is no moisture trapped in the concrete, if moisture is present dry

or apply Contite Moisture Barrier at a Contite Moisture Barrier min. of 300 microns D.F.T.

in 2 coats. Allow any repaired areas to cure before coating, prime

the entire surface using Elastoclad Elastoclad Elastoclad Clear Sealer Primer before Clear Sealer Primer

applying the Elastoclad HR.

METAL -Inspect metal surfaces for any signs of corrosion.

Corroded areas must be thoroughly cleaned and mechanically

prepared to remove all rust scale and surface contaminants. Apply

suitable anti-corrosive metal primer to entire surface area and allow

minimum 4 hours to cure e.g. Congard ST Congard ST before top coating.

For metal sheets such as zincalume apply etching primer such as

Elastoclad 160 Primer Elastoclad 160 Primer before coating.

Proper preparation of the roof deck is essential to the long term

performance of any roofing system.

Any concrete and metal roofs with existing asphalt, bituminous or

water based coatings must be water jet power-washed or scraped

to assure proper adhesion of the Elastoclad HR Waterproof

Ceramic Coating System

Furthermore, metal roof areas subject to surface rust should be

treated with Congard ST. Congard ST This will protect the long term integrity

of the affected areas to prevent further rust deterioration.

Metal roofs with loose and defective bolts, screws, and fastener

heads must be tightened or replaced and sealed. All loose seams

should be secured with additional fasteners or lap screws. Finally,

any open seams which remain must be sealed with Conflex LM or Conflex LM

reinforced with Elastoclad and Elastoclad Elastoclothe Elastoclothe polyester membrane

fabric to ensure a strong and durable waterproofing seal protection

over areas subject to thermal movement and shearing activity.

Once all fasteners, seams and openings are properly sealed, the

metal deck is watertight. The roof should now be coated using

Elastoclad HR.

Elastoclad HR may Elastoclad HR be applied using a brush, roller or airless spray. In some circumstances, particularly if applying by airless spray equipment, the viscosity of Elastoclad HR may warrant Elastoclad HR the addition of 5-10% of water for improved spray viscosity. In accordance with conventional good coating practices, it is recommended Elastoclad HR be Elastoclad HR applied in 2 coats to avoid pin holing and other imperfections that may result due to surface variations

The optimal thicknesses are as follows applied in 2 coats. These will also provide long life in various atmospheric conditions

20 Litre plastic pails.

| Surface | Min. DFT |

|---|---|

| Metal Wall Cladding | 300 micron |

| Metal Roof Deck | 300 micron |

| Cement Wall Render | 300 micron |

| Concrete Roof Deck | 300 micron |

| Asbestos Roof | 300 micron |

Apply only between 5° - 40° C ambient. If temperatures exceed this range contact your technical sales representative. Elastoclad HR should be kept tightly sealed and stored in a cool dry place. HR Always wear protective clothing, gloves and goggles during use. Do not use in unventilated areas. Please refer to Material Safety Data Sheet for detailed safety precautions.

Certified by

ISO 9001 : 2000 Cert . No. 04100 2001 0136 Quality Management System Certified

Elastoclad HR coating provides measurable thermal resistance and energy saving by deflecting heat and cold and significantly reducing substrate thermal radiation penetration.

is a successful hybrid of the highest quality acrylics and space age ceramics developed in response to the needs of Space Exploration programme.